Walk-in coolers represent a substantial investment for any business handling perishable inventory. These critical refrigeration systems run continuously, maintaining precise temperatures that protect thousands of dollars in food products, pharmaceuticals, or other temperature-sensitive goods. A single breakdown costs businesses far more than the repair itself; spoiled inventory, lost revenue, and disrupted operations create financial impacts that reach into thousands of dollars within hours.

Preventive maintenance transforms walk-in coolers from potential liabilities into reliable assets that perform efficiently for decades. The difference between a cooler that lasts 15-20 years and one that requires replacement after 8-10 years comes down entirely to consistent, systematic maintenance practices.

Understanding Walk-In Cooler Operating Demands

Walk-in coolers work under constant stress. Unlike residential refrigeration that cycles on and off throughout the day, commercial walk-ins operate continuously, managing frequent door openings, temperature fluctuations from incoming products, and the challenge of maintaining consistent temperatures across large spaces.

Professional commercial refrigeration service in Fresno addresses these unique demands through maintenance programs designed specifically for commercial applications. These systems process condensation continuously, battle against heat infiltration, and compensate for operational realities that residential equipment never encounters.

Daily Inspection Routines That Prevent Major Problems

Start each business day with a quick walk-in cooler inspection. Check temperature displays to ensure they read within your target range. Temperature fluctuations signal developing problems with refrigeration components, door seals, or control systems.

Inspect door gaskets daily for gaps, tears, or areas where seals don’t close completely against the frame. Damaged gaskets allow warm air infiltration that forces refrigeration systems to work harder, increasing energy consumption and accelerating component wear. Replace damaged gaskets immediately rather than waiting for complete failure.

Walk through the cooler and check for water accumulation on the floors. Standing water indicates drain line problems that require prompt attention. Blocked drains cause water backup, ice formation, and potential structural damage to cooler floors and surrounding areas.

Weekly Maintenance Tasks for Optimal Performance

Clear drain lines weekly to prevent clogs that cause water backup and ice formation. Pour approved drain line cleaner through floor drains and follow manufacturer recommendations for proper dilution and contact time. Blocked drains rank among the most common walk-in cooler problems and the easiest to prevent through consistent attention.

Clean evaporator coils weekly to maintain heat transfer efficiency. Dust, debris, and airborne particles accumulate on coil surfaces, creating insulating layers that reduce cooling capacity. Use soft brushes to remove buildup without damaging delicate coil fins. Bent fins restrict airflow and reduce system efficiency.

Inspect all visible electrical connections for signs of corrosion, loose wires, or damaged components. Moisture and temperature cycling create conditions where electrical problems develop gradually. Early detection prevents failures that shut down coolers completely.

Monthly Deep Maintenance Procedures

Schedule monthly deep cleaning that goes beyond daily and weekly tasks. Remove all shelving and thoroughly clean interior walls, floors, and ceilings. This prevents mold and bacteria growth that contaminates products and creates health code violations during inspections.

Examine door hinges and ensure they operate smoothly without binding or excessive play. Lubricate hinges according to the manufacturer’s specifications. Properly maintained hinges keep doors aligned with frames, maintaining seal integrity and preventing air infiltration.

Check the condensate drain pan condition monthly. These pans collect water removed from air during the cooling process. Buildup in drain pans creates environments where bacteria and mold thrive, potentially contaminating your cooler and the products stored inside.

Inspect insulation around door frames and anywhere refrigeration lines penetrate walls. Damaged insulation allows heat transfer that increases cooling loads unnecessarily. Address insulation problems promptly to maintain energy efficiency.

Quarterly Professional Service Requirements

Engage professional technicians quarterly for a comprehensive system evaluation. Trained technicians check refrigerant levels, test safety controls, measure amp draw on compressors and fan motors, and identify developing problems before they cause breakdowns.

Professional service includes cleaning condenser coils thoroughly using methods and equipment beyond typical facility maintenance capabilities. Condenser coils accumulate grease, dust, and debris that standard cleaning cannot fully remove. Professional cleaning restores heat rejection efficiency critical for system performance.

Technicians calibrate temperature controls during quarterly service, ensuring your cooler maintains target temperatures accurately. Control drift over time causes temperature variations that stress refrigeration systems and risk product safety.

Professional service also verifies proper refrigerant charge. Refrigerant levels affect cooling capacity, energy efficiency, and compressor longevity. Low refrigerant forces systems to run longer cycles, increasing energy costs and accelerating wear on mechanical components.

Critical Components Requiring Special Attention

Evaporator and condenser fan motors require regular inspection and maintenance. Listen for unusual noises indicating bearing wear or blade imbalance. Motors that fail cause immediate cooling loss and risk product spoilage if problems occur outside business hours.

Monitor compressor performance through amp draw measurements and by listening for changes in normal operating sounds. Compressors represent the most expensive walk-in cooler component. Detecting problems early allows repairs that prevent complete compressor failure, requiring full replacement.

Door sweeps and threshold seals protect against air infiltration at floor level. These components wear faster than overhead seals due to foot traffic and contact with carts or equipment moving through doorways. Replace worn sweeps before they create significant energy waste.

Energy Efficiency and Cost Control

Properly maintained walk-in coolers consume substantially less energy than neglected units. Dirty coils alone reduce efficiency by 25-40%, translating directly to increased utility costs month after month. The energy waste from deferred maintenance often exceeds maintenance service costs within a single year.

LED lighting retrofits reduce cooling loads while providing better visibility inside coolers. Traditional lighting generates heat that refrigeration systems must remove. LED fixtures produce minimal heat while lasting significantly longer than conventional bulbs, reducing maintenance needs.

Install strip curtains on high-traffic walk-in cooler doors. Strip curtains reduce air exchange when doors open frequently throughout the day. This simple addition cuts cooling loads substantially in busy commercial kitchens or warehouses.

Temperature Monitoring and Record Keeping

Install reliable temperature monitoring systems with remote alerts. Modern monitoring sends notifications when temperatures drift outside acceptable ranges, allowing immediate response before product losses occur.

Maintain detailed temperature logs that document cooler performance over time. These records help identify gradual temperature drift that signals developing problems. Health inspectors also require temperature documentation demonstrating consistent proper storage conditions.

Temperature patterns reveal information about cooler performance. Short cycling indicates potential refrigerant problems or control issues. Extended run times suggest dirty coils, damaged door seals, or refrigerant loss. Professional technicians use temperature pattern data to diagnose problems accurately.

Seasonal Maintenance Considerations

Texas summers place extraordinary demands on walk-in coolers. Higher ambient temperatures increase cooling loads significantly, forcing refrigeration systems to work harder throughout the season. Schedule professional service before peak summer heat to ensure systems handle increased demand reliably.

Inspect outdoor condensing units before summer to ensure they’re ready for extreme heat. Clear vegetation, debris, and obstructions from around outdoor units. Adequate airflow around condensing units is essential for proper heat rejection during high-temperature periods.

Winter months provide opportunities to address maintenance items that require extended cooler downtime. Use slower business periods to tackle projects like door replacement, insulation upgrades, or component refurbishment that would be difficult during peak seasons.

Staff Training for Long-Term Success

Educate staff about practices that protect walk-in cooler performance. Train employees to close doors promptly, avoid propping doors open, and report any unusual sounds, temperature changes, or visible problems immediately.

Establish clear procedures for product storage that promote proper airflow throughout the cooler. Overpacked coolers restrict air circulation, creating warm spots where products may not remain at safe temperatures. Proper organization protects products and reduces strain on refrigeration systems.

Teach staff to recognize early warning signs like frost buildup, water on floors, unusual sounds, or temperature variations. Early reporting allows you to address minor problems before they escalate into emergencies requiring after-hours service calls.

The Financial Impact of Preventive Maintenance

Walk-in cooler maintenance costs appear as line items on operational budgets, making them targets for cost-cutting measures. This thinking proves expensive. Emergency repairs during business hours cost substantially more than scheduled maintenance visits. Product losses from even a single breakdown often exceed annual maintenance program costs.

Preventive maintenance extends equipment lifespan by years. A cooler consistently maintained operates efficiently for 15-20 years or longer. Neglected coolers often require major repairs or complete replacement after just 8-10 years. The difference in total cost of ownership is substantial.

Energy savings from proper maintenance accumulate month after month. A well-maintained cooler consumes 20-30% less electricity than a neglected unit. Over the years of operation, these savings exceed maintenance costs many times over.

Documentation and Compliance

Maintain comprehensive maintenance records for every service, repair, and inspection performed on your walk-in cooler. Documentation demonstrates due diligence during health inspections and protects warranty coverage for major components.

Health departments require documented temperature monitoring and maintenance records. Detailed logs prove you maintain proper storage conditions consistently. Missing documentation creates compliance problems during inspections, regardless of actual cooler performance.

Warranty coverage for refrigeration equipment typically requires proof of regular professional maintenance. Manufacturers deny warranty claims when maintenance records don’t demonstrate consistent service. The cost of a single major repair denied under warranty can exceed years of maintenance expenses.

Frequently Asked Questions

How often should walk-in coolers receive professional maintenance?

Schedule professional walk-in cooler maintenance quarterly for optimal performance and longevity. Facilities with heavy use or challenging environmental conditions may benefit from service every two months to prevent problems and maintain peak efficiency.

What are the most common walk-in cooler problems that maintenance prevents?

The most common preventable problems include blocked drain lines causing water backup, dirty coils reducing efficiency, refrigerant leaks decreasing cooling capacity, failed door gaskets allowing air infiltration, and compressor failures from neglected maintenance. Regular service addresses these issues before they cause breakdowns.

How long should a well-maintained walk-in cooler last?

Well-maintained walk-in coolers typically last 15-20 years with consistent professional service and proper daily care. The refrigeration systems may require component replacements during this time, but the overall structure and properly maintained equipment provide decades of reliable service.

Why does my walk-in cooler run constantly but struggle to maintain temperature?

Constant running with poor temperature control indicates dirty condenser or evaporator coils, low refrigerant levels, failed door gaskets, damaged insulation, or compressor problems. Professional diagnosis identifies the specific cause and prevents product losses from inadequate cooling.

Can I perform walk-in cooler maintenance myself or do I need a professional?

Business staff can handle daily inspections and basic weekly cleaning tasks. However, quarterly professional service is essential for refrigerant system checks, electrical component inspection, control calibration, and thorough coil cleaning that requires specialized equipment and expertise.

Protect Your Walk-In Cooler Investment

Walk-in cooler preventive maintenance protects substantial equipment investments while ensuring the reliable performance your business depends on. Systematic maintenance prevents breakdowns, extends equipment life, reduces energy costs, and protects valuable inventory from temperature-related losses.

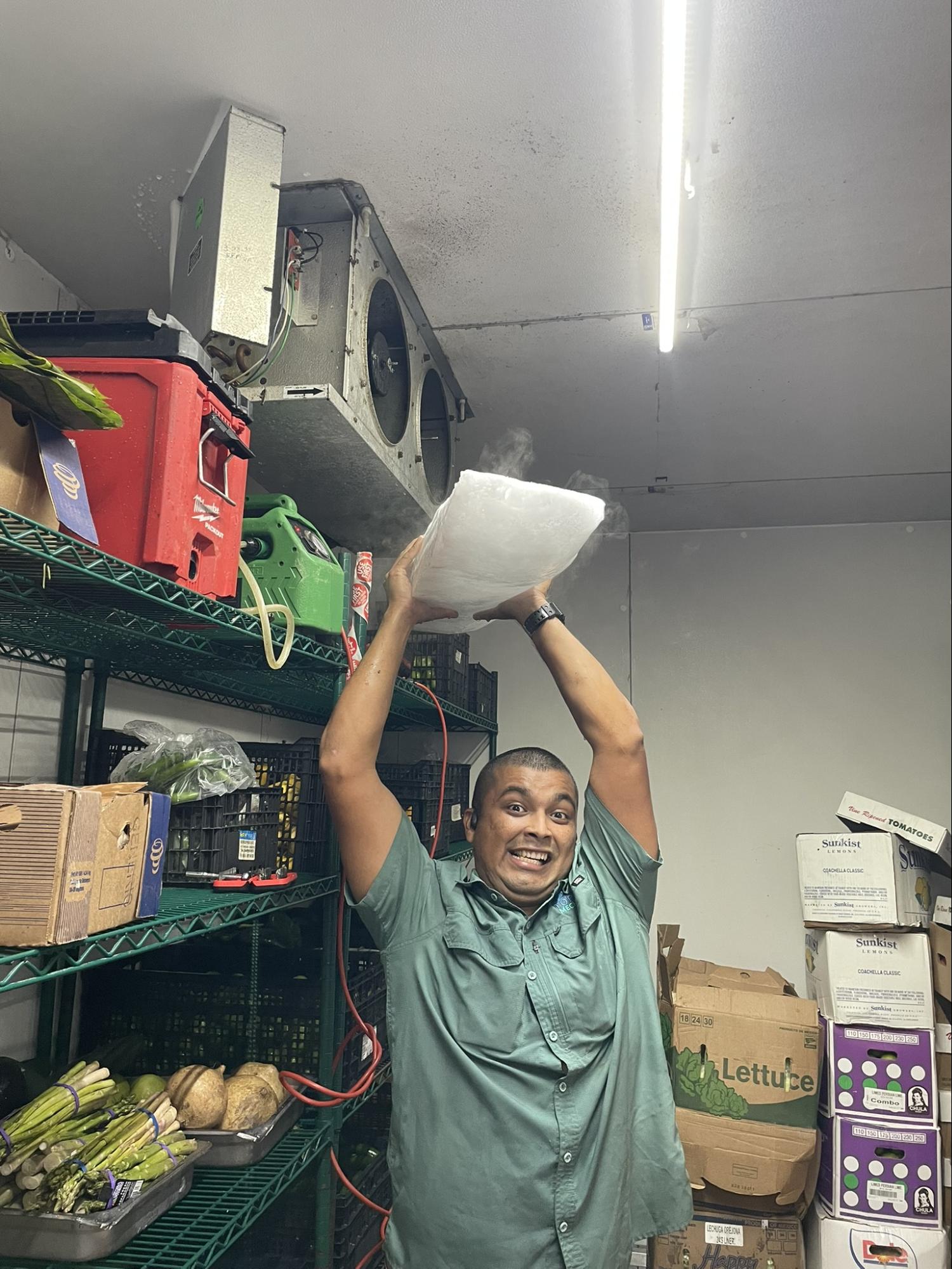

Top Pick Mechanical delivers expert commercial refrigeration maintenance for businesses throughout Fresno and surrounding Texas communities. Our experienced technicians understand commercial walk-in cooler demands and provide maintenance that keeps your systems running efficiently year-round. We respond quickly when problems develop and work to minimize operational disruptions while protecting your products and business.

Contact Top Pick Mechanical at 713-469-0024 to schedule walk-in cooler maintenance that extends equipment life and delivers reliable performance when your business needs it most.